Vector 3D

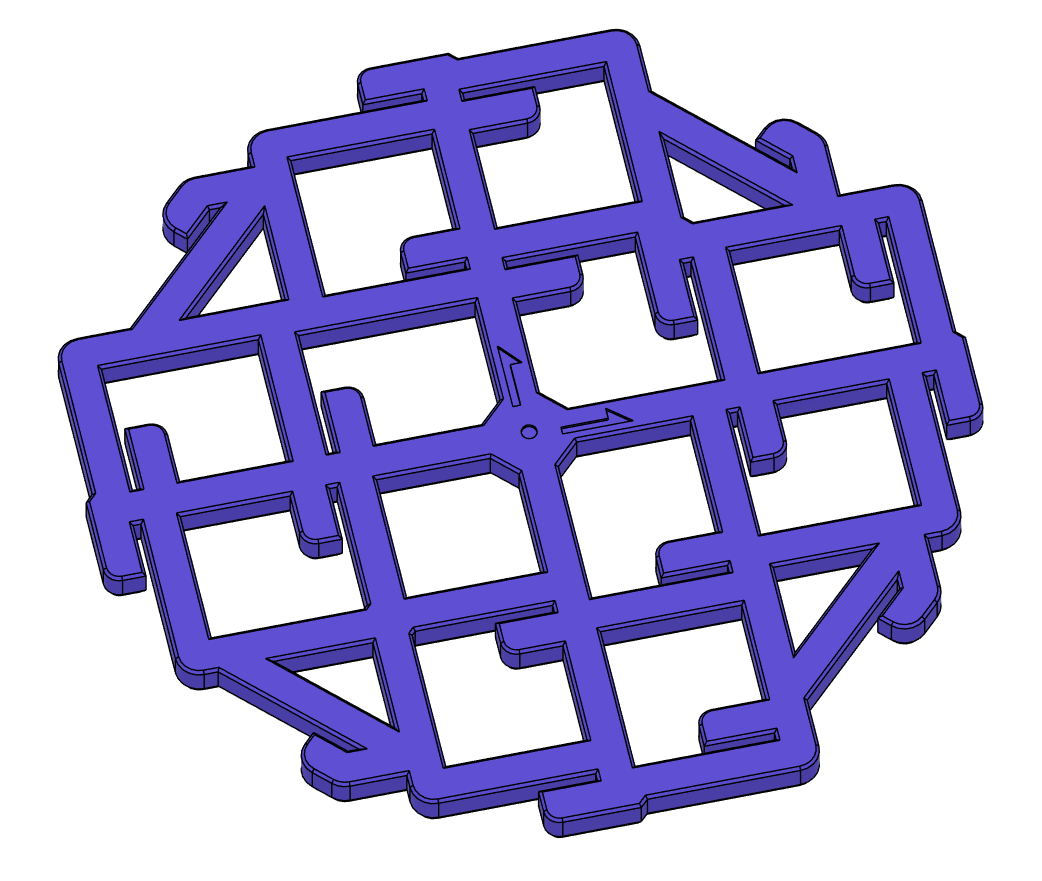

Califlower Calibration Tool Mk1

Califlower Calibration Tool Mk1

Couldn't load pickup availability

This product is old, See the new Califlower Mk2 here: https://vector3d.shop/products/califlower-calibration-tool-mk2

If you already purchased a newer version of Califlower use the following code (califlower-offline) to get it for free. You need to be logged in with your account for this to work.

About Califlower Mk1

The "Vector 3D Califlower Mk1 Calibration Tool" is an STL file and spreadsheet calculator to help you with printer calibration and testing. Included is documentation in the form of a spreadsheet calculator to identify and correct printer scale and skew accuracy. Includes the Califlower calibration STL file and Calculator Spreadsheet (in Excel and Libre office formats)

Slicer Compatibility

Size is typically fixed in the slicer, below is the compatibility chart

| Slicer | Fix Size | Ease |

| Orca Slicer | Yes | Easy |

| Prusa Slicer | Yes | Easy |

| Bambu Studio | No (switch to Orca slicer)* | Not possible |

| Cura | No (switch to alternative) | Complex |

*Orca Slicer can sign in with Bambu account and easily transfer all profiles and printers and works basically the same, just better!

Firmware Compatibility

Skew is typically fixed in the printer firmware, below is the compatibility chart.

| Firmware | Fix Skew | Ease |

| Marlin | Yes | Easy - Complex* |

| RepRap Firmware | Yes | Easy |

| Klipper | Yes | Easy |

| Bambu | Yes | Easy |

*In some cases Marlin will need to be recompiled to add skew correction feature which can be a complex operation.

Language Note

If you work with a numerical system that uses a comma (,) as the decimal separator, such as in Europe, then you will find that the spreadsheet places commas where the firmware requires a full stop/decimal point. For example, 10.45mm will become 10,45mm. See this Microsoft help document on how you can temporarily change this to use different separators https://support.microsoft.com/en-us/office/change-...

More info

More info

Language Note

If you work with a numerical system that uses a comma (,) as the decimal separator then you will find that the spreadsheet places commas where the firmware requires a full stop/decimal point. For example, 10.45mm will become 10,45mm. See this Microsoft help document on how you can temporarily change this to use different separators https://support.microsoft.com/en-us/office/change-...

Downloads

Downloads

N/a

Share

Quite clever design to make measuring everything easy and repeatable.

Not everyone needs this, but if you need precision and accurate sizes when 3D printing, this is the absolute best calibration tool around. Simple and cheap to print, and incredibly easy to calibrate once it's printed. Very clear and thorough instructions

It's a cool tool and print sizes have improved some, but I still can't quite get hole sizes to print correctly.

Awesome tool and very easy to follow instructions.

Dimensions are accurate. Excel form is so comfortable.